Overview

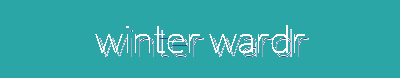

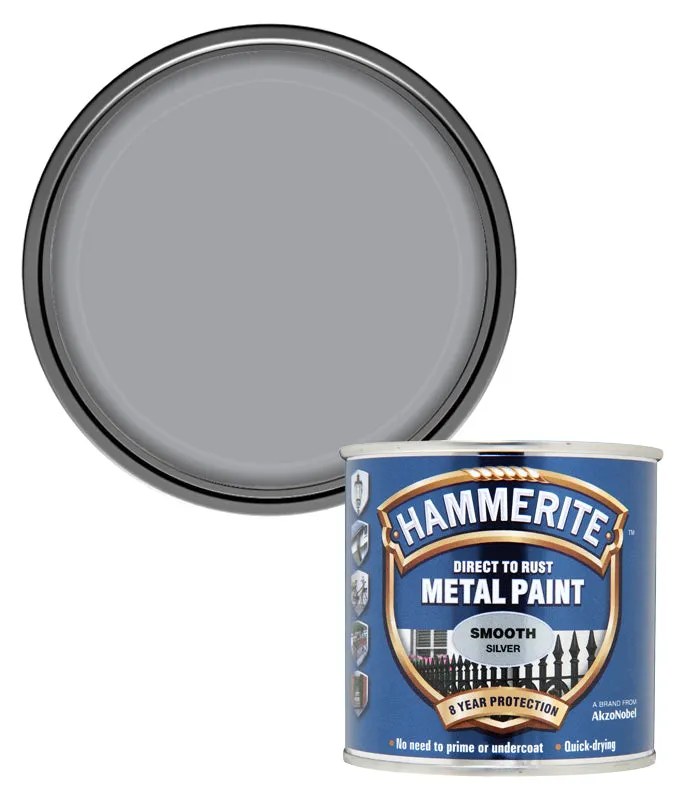

Hammerite Smooth Direct to Rust Metal Paint is specially formulated to perform as primer, undercoat and topcoat in one. It’s a smooth gloss finish which will retain its sheen for years with excellent weather resistance. It’s durable, corrosion resistant decorative coating for ferrous and non-ferrous metals. Primer or undercoat are not necessary for sound surfaces.

If you can't find the colour you're looking for here, try our

- Hammerite smooth gloss finish

- Ultra tough

- Easy to use

- 8 year corrosion protection

- Excellent weather resistance

| Area | Exterior |

| Recommended Use | Metal Surfaces |

| Base | Solvent based |

| Coverage | 5m² per litre |

| Drying Time | Touch dry 1-2 hours |

| Re-Coat Time | 4 hours |

| Recommended Coats | 1 or 2 coats |

| Application Method | Brush |

| VOC Levels | High |

| Clean Up | Remove as much paint as possible from the brush before cleaning with brush cleaner |

Preparation

Always ensure the surface to be treated is clean, dry and free from any dust, dirt, grease, flaking paint or rust.

- Sand/abrade smooth surfaces and remove any loose rust or flaking paint.

- Remove dirt, dust and grease with a solution of diluted detergent.

- Rinse with clean water and allow time to dry.

- Hammerite smooth metal paint is available in a wide range of colours, as screen resolutions can vary we always recommend testing the paint prior to full application to ensure you are happy with the finished results.

Application

Before application of Hammerite Smooth Direct to Rust Metal Paint test a patch onto the painted surfaces and leave for 1 hour. If there is no reaction continue to apply, if there is a reaction with the previous paint all paint must be removed before applying Hammerite Direct to Rust Metal Paints.

- For Bare Zinc, aluminium and galvanised surfaces firstly apply .

- Do not apply in temperatures below 8°C or above 25°C.

- Lightly stir before use.

- Do not thin, this smooth metal paint has been supplied ready to use.

- On previously painted metal in a sound condition 1 coat should be sufficient.

- On bare or rusty metals 2 coats may be required.

- For maximum durability ensure all edges and corners are adequately covered.

- Do not over apply as sagging will occur, be especially careful on veretical surfaces.

Note: Always follow the manufacturer instructions found on the tin.